A Shift in How We Train?

Anyone who’s ever stepped inside a full-scale simulator knows how impressive they are. A cockpit replica with real switches, or a medical dummy that responds to procedures, gives you a sense of training that feels close to the real world. For a long time, this was the only way to prepare people for high-stakes jobs.

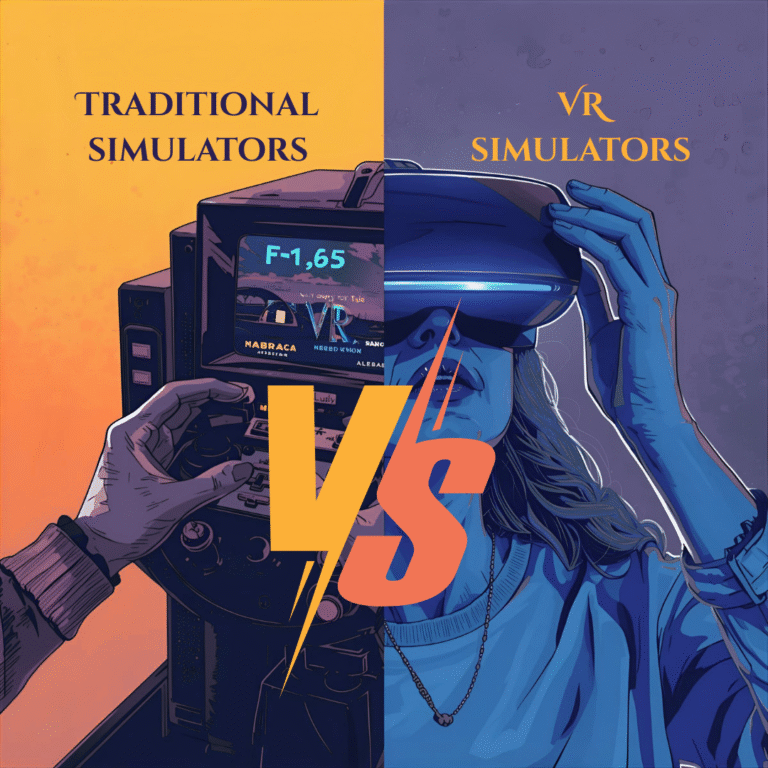

But things don’t stay still for long in technology. Virtual reality has entered the training world, and it’s starting to challenge the old setups. The big question isn’t whether VR simulators are “cool” it’s whether they can really compete with the traditional models that companies have trusted for years.

When it’s time for the real thing, they’re ready. Faster fixes, fewer screw-ups, and less downtime.

What Traditional Simulators Do Well?

Traditional simulators are built to mimic one machine or scenario as closely as possible. If you’re learning to fly, you sit in a mock cockpit. If you’re studying surgery, you practice on physical mannequins. That physical element is their biggest strength. You can touch, feel, and operate controls exactly the way you would on the real thing.

The downsides are just as obvious. They’re expensive to build, costly to maintain, and once you’ve set one up, it usually trains for a single purpose. If your needs change, or if you want to train more people at once, it gets tricky.

Enter VR Simulators

VR takes a very different approach. Instead of building physical hardware, it drops you into a digital environment through a headset. One minute you’re on an oil rig, the next you’re in a warehouse, and later you could be standing in a hospital ward. The hardware doesn’t change, only the software does.

That flexibility is the main reason companies are paying attention. Updates are faster, costs stay lower, and you don’t need a massive space to house the system. Plus, you can scale training across multiple sites without moving equipment around.

Side-by-Side: The Everyday Differences

When you compare the two, the strengths line up pretty clearly:

Hardware realism: traditional simulators still win here. If your job depends on memorizing the feel of a switch or lever, nothing replaces the real thing.

Immersion: VR takes the crown. You’re surrounded by a 360-degree world, not just sitting in front of a replica.

Cost and scale: VR comes out ahead. Traditional simulators are limited, expensive, and not easily intergratable.

Flexibility: you can reprogram a VR scenario in days. A traditional setup may never adapt.

Where Each One Fits?

So, which is “better”? In truth, it depends on the goal. Airlines aren’t about to ditch full-cockpit simulators, those are essential. But if you’re training a large workforce on safety protocols, equipment checks, or emergency drills, VR will likely deliver more value.

Some organizations are already combining both, keeping traditional simulators for advanced or tactile training while using VR for routine practice and scale. That blended model is becoming the most practical path forward.

Why More Companies Are Leaning Toward VR?

Cost is one part of the story, but it’s not the whole thing. Businesses also like that VR reduces downtime, lowers risks in dangerous environments, and speeds up the learning curve for new employees. Add performance tracking and analytics into the mix, and VR turns into more than a training tool, it becomes a strategy for building safer, more capable teams.

Check this out for more details: Click here

Final Word

The debate around VR simulators vs traditional simulators isn’t about replacing one with the other. It’s about figuring out which tool fits the job. Traditional systems will always be needed where hardware familiarity is non-negotiable. But for flexibility, cost savings, and scalability, VR is quickly proving itself as the smarter choice.

If you’ve been sitting on the fence, it might be time to see where a VR simulator could slot into your own training programs.

If you are ready to explore how VR training can work for your business, contact us to get started.